Refrigeration

consolidation and distribution

Specialist in temperature-controlled logistics since 1949.

In a few figures:

million turnover 2023

0

employees including 190 drivers

0

temperature-controlled platforms

0

gray cards

0

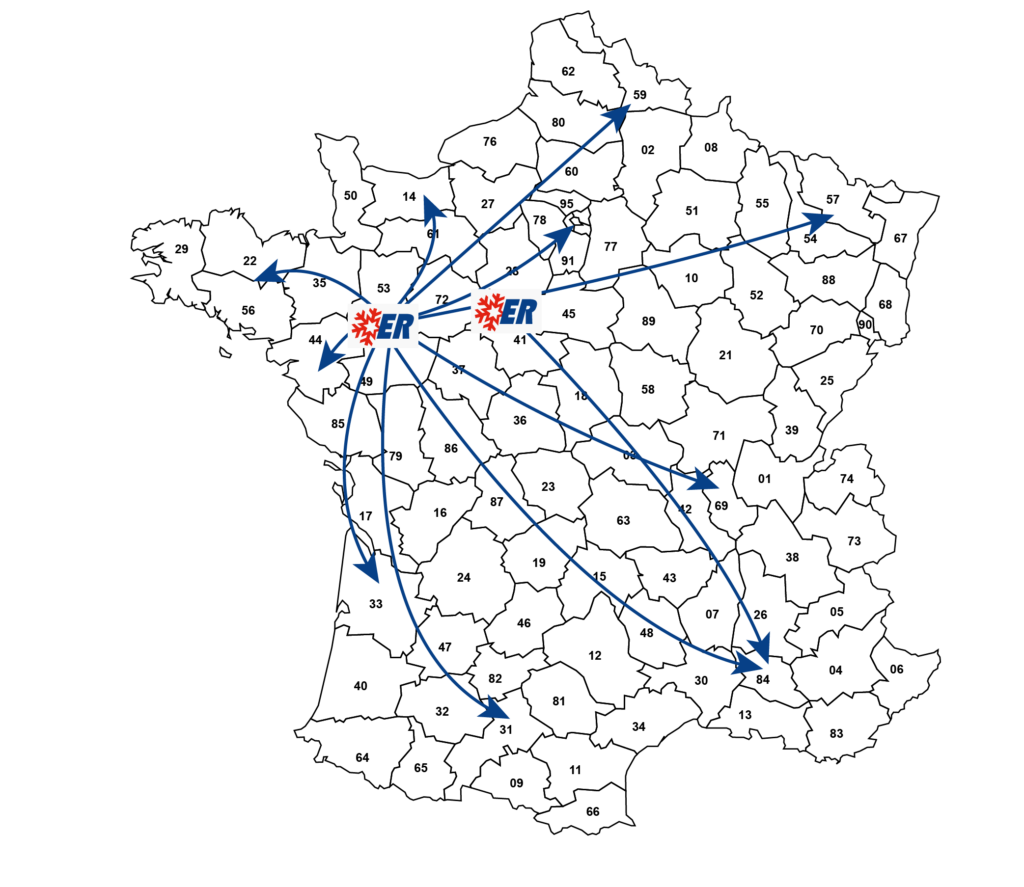

plateformes : Le Bailleul (72), Cherré-Au (72), Ingré (45), La Flèche (72)

REFRIGERATED TRANSPORT

Our know-how and our orientations:

- Massification of flows collected from our various hubs, oriented on our 4 platforms with a total surface area of 14,000 m2.

- Constitution of batches and organization of routes, to carry out online deliveries making it possible to propose a transport plan with more flexible departures while meeting the requirements of different just-in-time flows.

- Our added value: direct delivery without interruption from our sites.

- Our targets: mass distribution platforms, wholesalers, manufacturers within A/A and A/B lead times, over a major part of the national territory.

- Organization of return flows in groupage, half-lots and full lots which allows us to expand our offers and our scope of activity.

- Processing on average more than 1,600 positions and 1,900 tons of goods per day, or 595,000 tons or 1,900,000 pallets transported per year.

Our specificity: direct delivery without interruption:

By massification on our platforms of Bailleul (72), Cherré-Au (72) and Ingré (45), the flows collected in the regions of the great West, the North of the Paris Region, the Center and the Rhône-Alpes generate more than 150 trips per day.

Departures timed just in time depending on the distance from the delivery point.

More than 110 supermarket platforms, wholesalers and manufacturers are delivered every day within 24 hours.

REFRIGERATED LOGISTICS

Our services:

-

Storage of frozen products -20°C:

- Capacity of 5,000 pallets

- 22,500 m3

- 2,500 m2 in negative cold -

Storage of fresh products +2°+4°C:

- Capacity of 8,000 pallets - Co packing: 2 million packages on the La Flèche site

- Order preparation: 7 million packages on the La Flèche, Cherré-Au and Ingré sites

OUR ECO-RESPONSIBLE APPROACH

Our commitment to “reduce by 40%

CO2 emissions by 2030 »:

100% of our engine fleet meets EURO VI standards,

of which 40% runs on B100 biofuel (rapeseed)

Our energy reductions:

- Energy recovery system used for defrosting the evaporators, equivalent to 4 hours of consumption

- 2,200 m2 of voltaic panels installed on the Bailleul site (72), producing 480 k peak watts

- Switch to LED lighting on 100% of sites and installation of charging stations for cars

- Rainwater recovery allowing an 80% saving in consumption for exterior washing of trucks

Our HACCP approach:

- Temperature recorders with alert system on platforms and on board vehicles

- HACCP training

- Health protocols